The Science of Corrugated Strength: Why Gaylord Boxes Are Engineered to Hold Thousands of Pounds

This guide explains exactly why Gaylord boxes are so strong, supported exclusively by .edu, .gov, ASTM, TAPPI, and manufacturer technical sources.

Fact Check By Grok -> Here

What Makes Gaylord Boxes So Strong?

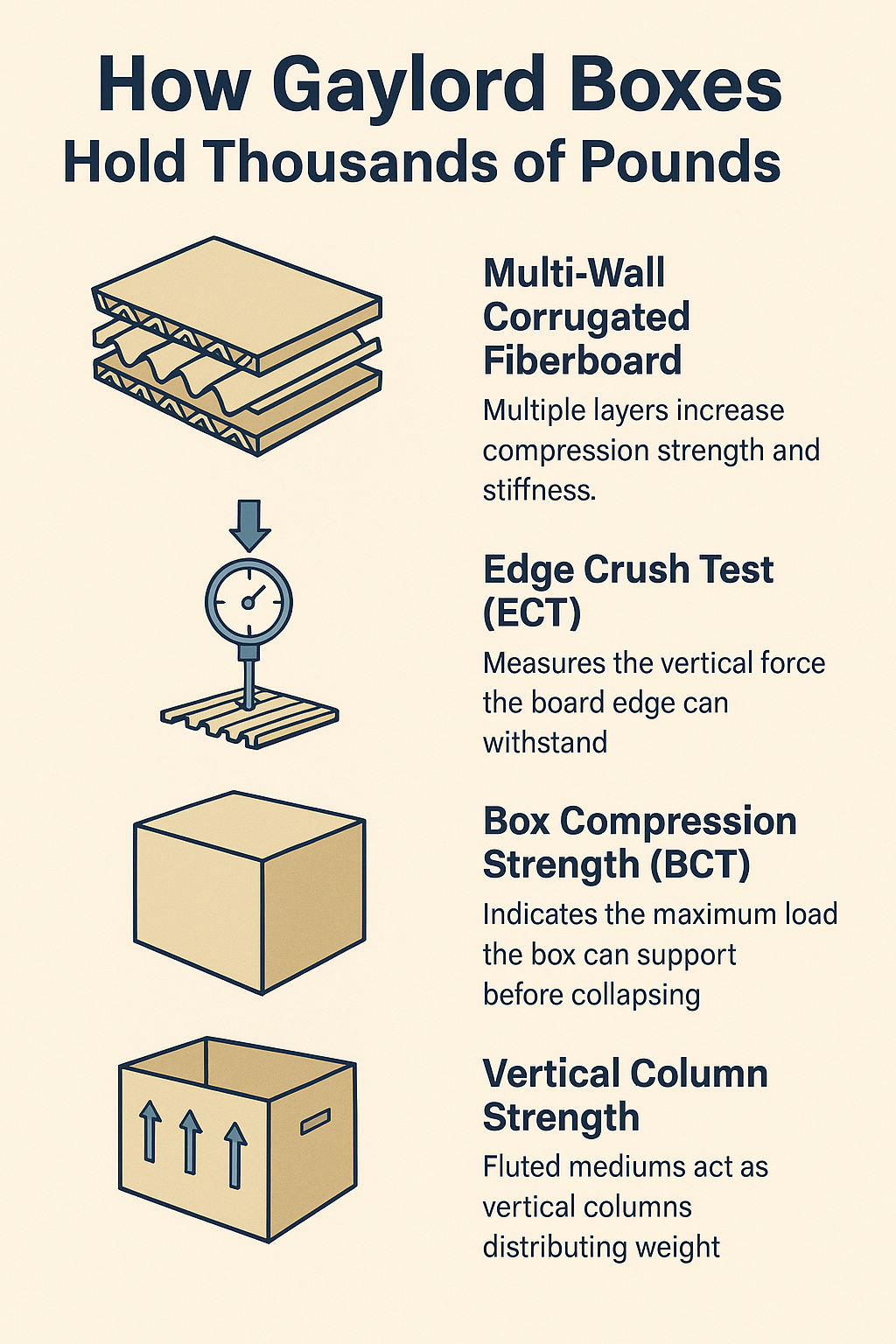

Gaylord boxes achieve high load capacity because they are made from multi-wall corrugated fiberboard engineered for extremely high edge crush resistance (ECT) and box compression strength (BCT). Their fluted mediums act like vertical I-beams, transferring load through reinforced corners. These properties are verified through standardized testing from ASTM, TAPPI, and decades of research from the USDA Forest Products Laboratory.

1. Corrugated Fiberboard: An Engineered Structural Composite

Corrugated fiberboard—used in every Gaylord box—is a high-strength composite material composed of:

- Outer linerboards

- Inner fluted mediums

- High-bonding adhesives

The USDA Forest Products Laboratory describes corrugated as a sandwich-structure system, where the flutes create thousands of micro-columns. This architecture dramatically increases:

- Vertical compressive strength

- Bending stiffness

- Resistance to buckling

This engineered structure is why corrugated bulk boxes outperform many rigid containers in stacking and vertical-load environments.

2. Multi-Wall Construction: Why Gaylord Boxes Outperform Standard Cartons

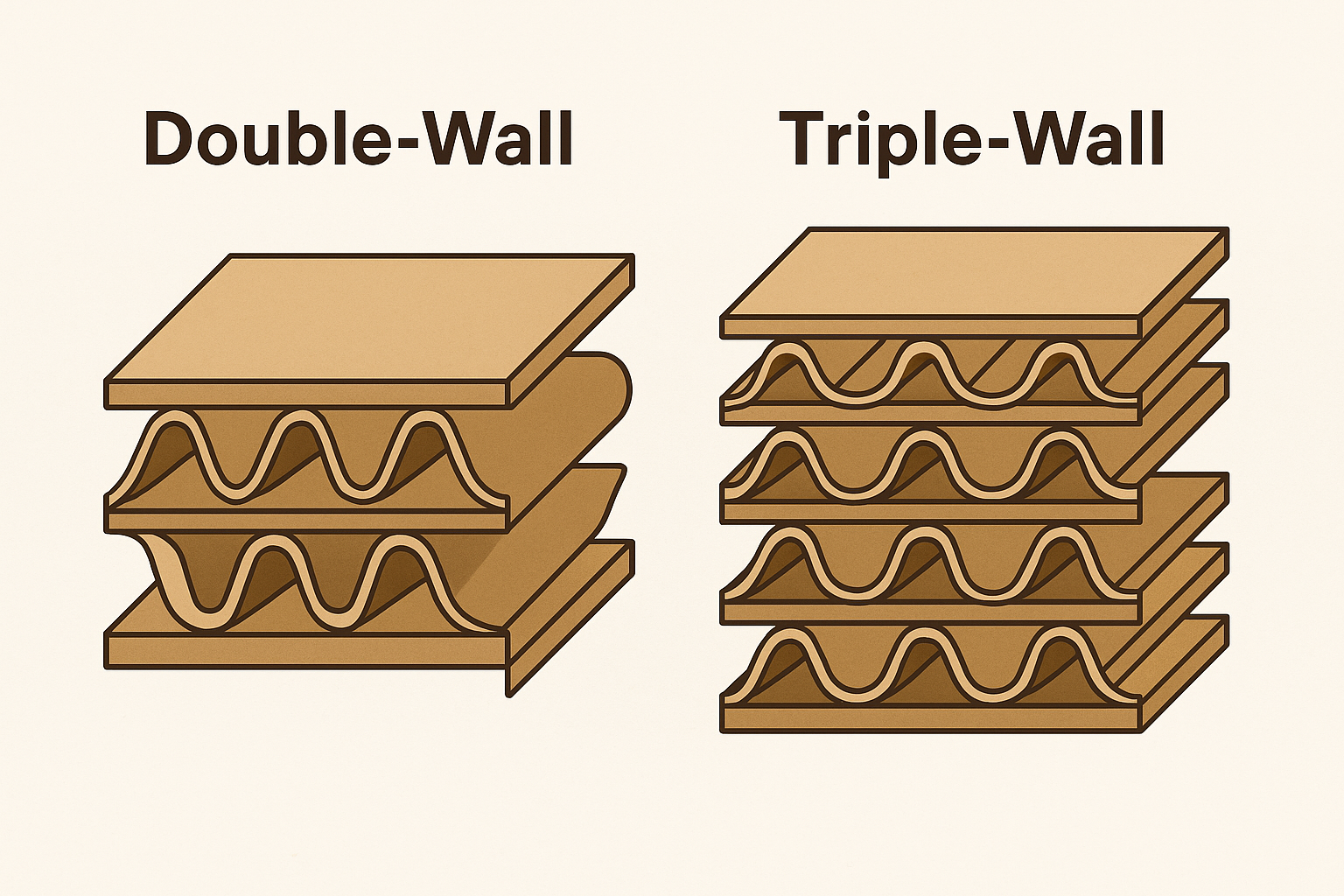

Typical shipping boxes use single-wall board. Gaylord boxes are built with:

- Double-wall (DW)

- Triple-wall (TW)

- Laminated heavy-wall corrugated

Research from the USDA Forest Products Laboratory confirms that additional wall layers significantly increase:

- Edge crush resistance

- Buckling resistance

- Compression strength under load

For industries handling plastics, metals, grains, or aggregates, triple-wall Gaylords provide the strength consistency required for safe, high-density loading.

3. ECT (Edge Crush Test): The First Predictor of Box Strength

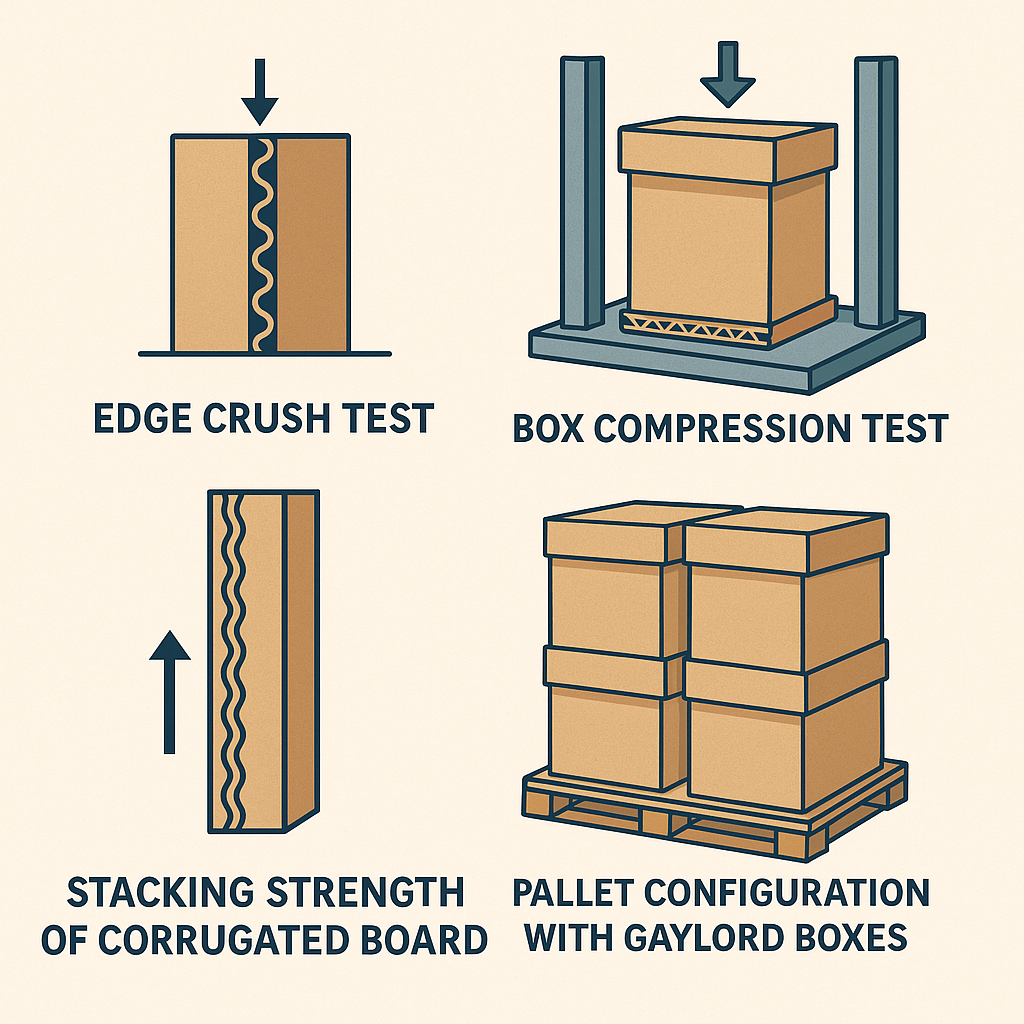

ECT measures how much vertical force a corrugated edge can withstand — a critical predictor of stacking strength and crush resistance.

How ECT is measured:

ECT is tested using TAPPI T 811 and TAPPI T 839, which quantify edgewise compressive strength. ECT values are then used within selection practices like ASTM D5639/D5639M to determine appropriate corrugated grades for given load requirements.

Typical ECT ranges:

- Single-wall: 32–44 ECT

- Double-wall: 48–61 ECT

- Triple-wall: 67–97+ ECT

High ECT values correlate strongly with:

- Higher stacking capacity

- Improved resistance to bulging

- More consistent load transfer

This is why ECT-90 triple-wall Gaylords are commonly designed to support 1,000+ pounds, and many configurations safely exceed 2,000 pounds, depending on dimensions and pallet conditions.

4. BCT (Box Compression Strength): The Core of Load Capacity

Box Compression Strength (BCT) measures how much downward force a box can withstand before collapsing.

The most widely used prediction model is the McKee formula, validated extensively by the USDA Forest Products Laboratory and refined through research at the Georgia Tech Institute of Paper Science and Technology.

The McKee model shows that BCT increases with:

- Higher ECT

- Greater board thickness

- Reinforced corners

- Optimized panel dimensions

In industry practice, engineers use McKee calculations to estimate strength and then verify performance through physical ASTM compression testing — ensuring Gaylord boxes perform predictably under real loads.

5. Laboratory Testing Confirms Real-World Performance

Universities and packaging labs — including the Clemson University Packaging Science Program — use compression equipment capable of applying tens of thousands of pounds of force to validate corrugated performance.

Key ASTM standards include:

- ASTM D642 — Measuring compression resistance of shipping containers

- ASTM D7030 — Short-term creep performance of corrugated containers under constant load (commonly applied to heavy-duty and triple-wall boxes)

These tests ensure Gaylord boxes meet required load, safety, and stacking specifications before entering industrial supply chains.

6. Moisture & Environmental Effects on Strength

Corrugated fiberboard is hygroscopic—it absorbs moisture. This significantly impacts performance.

Research from the USDA Forest Products Laboratory shows that high humidity can reduce compression strength by up to 50% in untreated corrugated.

For wet or high-humidity environments (produce, meat packing, outdoor storage), manufacturers such as:

produce water-resistant, wax-alternative, and laminated corrugated solutions to preserve load capacity.

7. The Physics Behind Why Gaylord Boxes Don’t Collapse

Gaylord box strength is driven by four core mechanical principles:

1. Vertical Column Strength

Each flute is a micro-column. Research from the USDA Forest Products Laboratory confirms this architecture greatly increases load-bearing capacity.

2. Increased Moment of Inertia

Thicker walls significantly boost bending stiffness — supported by studies from the Georgia Tech Institute of Paper Science and Technology.

3. System-Level Unit Load Behavior

Transport-packaging research shows that proper pallet and unit-load design significantly improves box stability and reduces racking forces.

4. Reinforced Corners & Joints

Box compression research and ASTM/TAPPI guidance consistently emphasize that edges and corners carry most of the load during stacking. Gaylord boxes therefore use stitched or glued seams, not simple fold joints.

8. Sustainability Benefits of High-Strength Bulk Packaging

Gaylord boxes are not just strong — they are highly sustainable.

High Recycling Rates

Corrugated boxes have the highest recovery rate of any U.S. packaging material, according to the EPA.

Lower Manufacturing Emissions

A life-cycle analysis from the Fibre Box Association reports a 50% reduction in per-box greenhouse gas emissions from 2006 to 2020.

Reuse Before Recycling

Peer-reviewed LCA research published in MDPI shows that reusing corrugated containers before recycling can significantly reduce total environmental impact.

For industrial users, this translates to:

- Lower packaging cost per use

- Lower carbon footprint

- Reduced solid waste

- More efficient bulk material management

Overview:

Gaylord boxes hold thousands of pounds because they are:

- Built from multi-wall engineered corrugated fiberboard

- Designed using validated strength models (ECT → BCT)

- Tested under ASTM and TAPPI standards

- Reinforced at corners, seams, and load-bearing points

- Optimized for palletized distribution environments

- Manufactured from highly recyclable materials with verified low environmental impact

Supported by research from USDA FPL, ASTM, TAPPI, Clemson, Georgia Tech, and major corrugated manufacturers, Gaylord boxes remain one of the most reliable and sustainable bulk-packaging options in modern supply chains.

Leave A Comment